Mingke Jingji (securities code: 001319. SZ) specializes in the stamping, welding and assembly of automobile precision stamping dies and auto parts. The group company has advanced die manufacturing technology and precision stamping technology to provide customers with integrated solutions for precision stamping dies and auto parts.

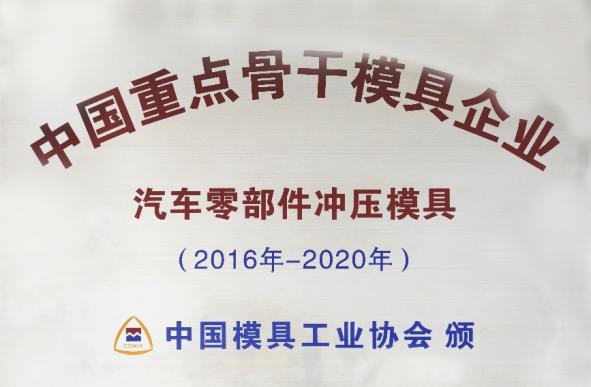

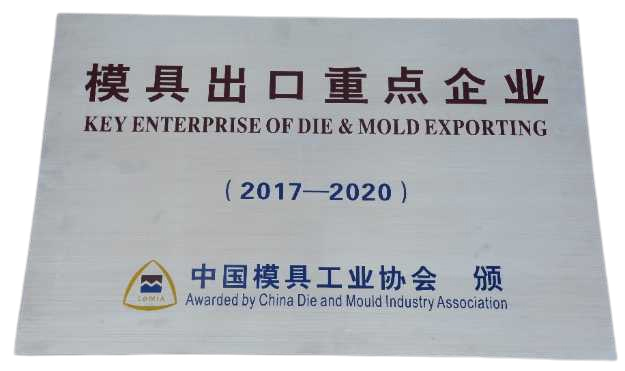

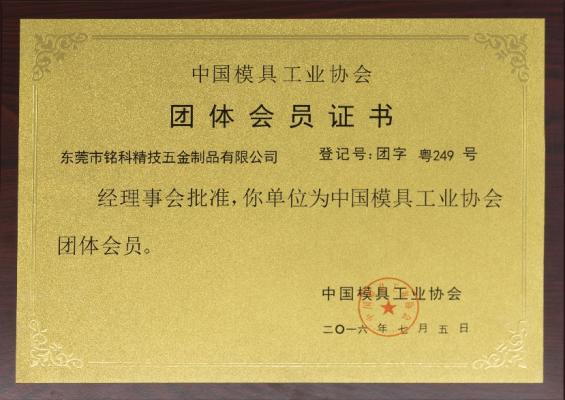

The Group has more than ten manufacturing bases in China, covering the six major automobile industry clusters in China. The Group has more than 1600 employees and an annual output value of more than 1 billion. Since its establishment, the Group Company has been guided by customer needs and has always taken independent research and development and technological innovation as the continuous driving force for development. It has been recognized as "National High-tech Enterprise", "Dongguan Municipal Multiplier Enterprise", "Dongguan Listed Enterprise", and has been rated as "China Key Key Mold Enterprise" by the China Mold Industry Association.

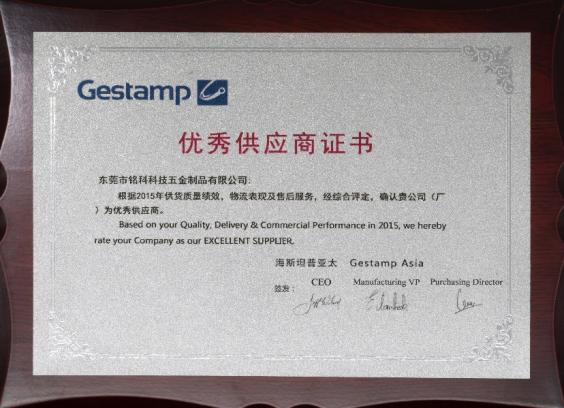

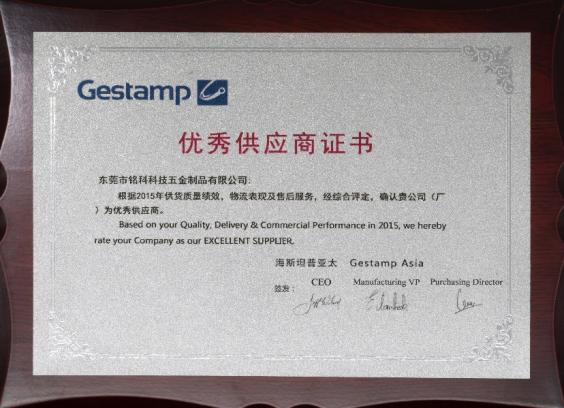

The group company was founded in 2003 and started with the operation of molds and parts related to consumer electronics. It entered the field of auto parts around 2008 and was unanimously recognized by customers. Relevant businesses gradually showed their scale. Since 2011, the group company's auto parts business has entered a period of rapid growth. In the field of automobile, the group company has been recognized by the world-famous first-tier suppliers of automobile parts, such as Magneti Marelli, Gestamp, Hiroshima Technology, Faurecia, Anduto, and Lingyun Industry, and has served BMW, Benz, Audi, Nissan, Honda, Toyota, General Motors, Xiaopeng Automobile, and Celes, providing them with precision automobile stamping dies and automobile parts. The business scope is distributed around: the United States, Spain, France, Germany, the Czech Republic, the United Kingdom, Mexico, Japan and other countries.

The root of an enterprise is "people". If there is no "people" in an "enterprise", it will "stop".

The competition of enterprises depends on "execution", and the products and services should be "you have nothing, you have something new, you have something new, and you have something fast

Diligence can make up for weakness, and adhere to the Mingke spirit of "talking nonsense and doing hard"!

We need to achieve high efficiency in production and office, relying on technological innovation and hard work, and relying on automatic wheels and punctuality.

"Faith" is "integrity", "loyalty" and "credibility". We Minke people should be honest with customers and loyal to enterprises, and build a reputation brand for enterprises and individuals.

Regardless of age and position, Mingke people are always full of sunshine to the enterprise, family, career and life, and maintain the passion of striving forward and upward.

Address: No. 180, Tianxin Road, Tangxia Town, Dongguan City

Email: winstech_19@winstechfield.com